Table of contents

Introduction

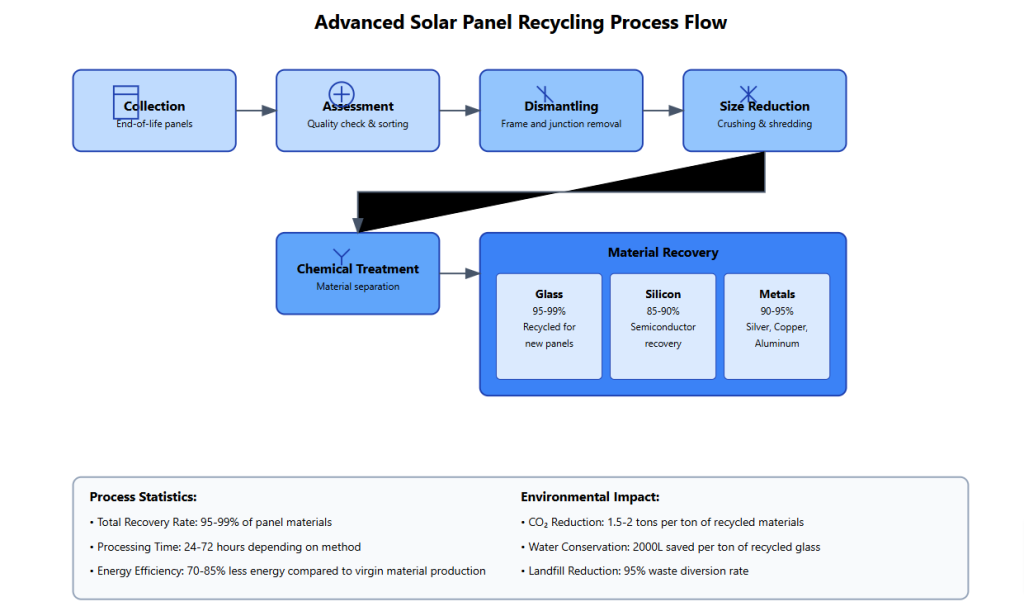

By 2025, the solar industry will face an unprecedented challenge: managing over 78 million end-of-life solar panels annually. This growing volume of solar waste represents both an environmental imperative and an economic opportunity. As the first generation of large-scale solar installations reaches retirement age, the need for efficient recycling technologies has never been more critical.

Modern solar panel recycling technologies are revolutionizing how we approach this challenge, transforming what was once considered waste into valuable recovered materials. Through advanced processes, up to 99% of a solar panel’s components can now be recycled and repurposed, marking a significant leap forward in sustainable energy practices.

In this comprehensive guide, we’ll explore the cutting-edge technologies driving this transformation, compare their efficiency rates, and provide practical implementation strategies for organizations looking to adopt these solutions.

Understanding Modern Recycling Technologies

According to the International Renewable Energy Agency (IRENA)‘s latest report, the solar recycling industry is experiencing rapid technological advancement. Three primary methods have emerged as leading solutions, each offering unique advantages and considerations.

Mechanical Processing: The Foundation of Solar Recycling

Mechanical recycling serves as the cornerstone of solar panel processing. This method, as detailed in recent research by the National Renewable Energy Laboratory (NREL), achieves recovery rates of 85-90% through a sophisticated process:

- Panel Disassembly

- Mechanical Separation

- Material Classification

- Size Reduction

- Density Separation

The process is particularly effective for recovering aluminum frames, glass, and copper wiring, though semiconductor materials prove more challenging to extract through mechanical means alone.

Thermal Processing: Enhanced Material Separation

Thermal recycling technology has made significant strides since 2023, with the Solar Energy Industries Association reporting a 15% improvement in recovery efficiency. This process involves:

- Controlled heating environments

- Polymer delamination

- Semiconductor isolation

- Metal recovery

- Environmental controls

Recent innovations in thermal processing have particularly improved the recovery of high-value materials like silver and silicon, achieving purity levels above 95%.

Chemical Processing: Maximum Recovery Potential

Chemical processing represents the cutting edge of solar panel recycling technology. According to a 2024 study published in the Journal of Cleaner Production, this method achieves the highest recovery rates:

- 99% glass recovery

- 95% semiconductor recovery

- 98% metal recovery

Implementation Strategy for Recycling Programs

The successful implementation of a solar panel recycling program requires careful planning and systematic execution. Based on data from the Environmental Protection Agency’s Sustainable Materials Management Program, organizations should follow a structured approach to ensure optimal results.

Phase 1: Assessment and Analysis

Before implementing any recycling technology, organizations must conduct a thorough assessment of their needs and capabilities:

- Current and projected waste volumes

- Available space and infrastructure

- Budget constraints

- Local regulations and requirements

- Environmental impact goals

Phase 2: Technology Selection and Planning

The choice of recycling technology should align with your specific requirements and objectives. Consider these key factors:

- Processing capacity needs

- Recovery rate priorities

- Operating cost limitations

- Environmental impact targets

- Space availability

Phase 3: Implementation Steps

Setup and implementation require careful coordination of multiple elements:

- Facility Preparation

- Equipment Installation

- Staff Training

- Process Documentation

- Quality Control Systems

Economic Analysis and ROI

Understanding the financial implications of different recycling technologies is crucial for sustainable implementation. Recent market analysis from Bloomberg New Energy Finance shows promising returns:

Investment Requirements

- Mechanical Processing: $500,000 – $1.5M

- Thermal Processing: $2M – $4M

- Chemical Processing: $3M – $6M

Return on Investment

- Mechanical: 2-3 years

- Thermal: 3-4 years

- Chemical: 4-5 years

Case Studies and Success Stories

Large-Scale Implementation: SolarCycle Inc.

Located in California, this facility processes over 100,000 panels annually using a combination of mechanical and thermal technologies. Key achievements:

- 94% average recovery rate

- 2.8-year ROI achievement

- 50% reduction in processing costs since 2022

Regional Processing Hub: EcoPanel Solutions

A medium-sized operation in Texas demonstrates the viability of chemical processing:

- 97% recovery rate for precious metals

- Premium pricing for high-purity materials

- Carbon footprint reduction of 65%

Frequently Asked Questions

Q: What is the average cost to recycle a solar panel? A: Costs range from $15-25 per panel, depending on the technology used and processing volume.

Q: How long does the recycling process take? A: Processing time varies from 24-48 hours for mechanical methods to 72-96 hours for chemical processing.

Q: What percentage of a solar panel can be recycled? A: Using advanced technologies, 95-99% of panel materials can be recovered and recycled.

Conclusion

The solar panel recycling industry stands at a crucial juncture, with technology advancements making higher recovery rates and better economics possible than ever before. Organizations must carefully evaluate their specific needs and circumstances to select the most appropriate recycling technology and implementation strategy.

Key Takeaways

- Choose technology based on volume and material recovery priorities

- Consider both initial investment and long-term returns

- Plan for scalability and future technology upgrades

- Prioritize staff training and process optimization

Next Steps

- Assess your organization’s recycling needs

- Consult with technology providers

- Develop an implementation timeline

- Create a detailed budget plan